A business made of hope and audacity!

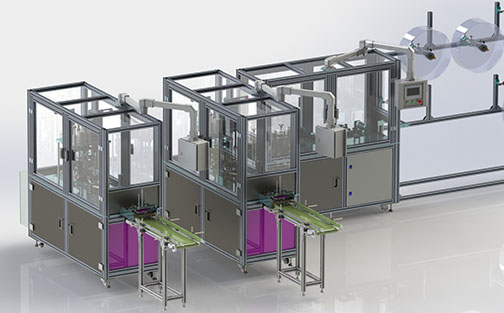

Automatic High Capacity Surgical Mask Production Line.

Case study - Automatic High Capacity Surgical Mask Production Line.

On occasion, more unfortunate periods allow us to catch a glimpse of other dimensions. A moment of crisis ought to be seen as an opportunity and the fear of moving into new territories must be overcome.

APINEQ has stepped out of its comfort zone and reinvented its business model amidst the Covid-19 pandemic.

Upon identifying the shortfall in the production of surgical masks in Europe, APINEQ brought the team together and launched the Surgical Mask Production project.

Led by Engineer Vaz Martins, APINEQ’s founder, the team of professionals experienced in innovation and the creation of public and hospital safety materials, committed themselves with absolute dedication.

In May, the first prototype of the 1st 100% national production machine, named the Automatic Production Line of High Capacity Surgical Masks, was created, and was swiftly launched into the export market.

With modular setup and easy installation, the production line of (adult size) surgical masks allows the capacity to automatically produce sterile masks, individually wrapped in plastic or packed in batches of 50 in a cardboard box.

The equipment consists of:

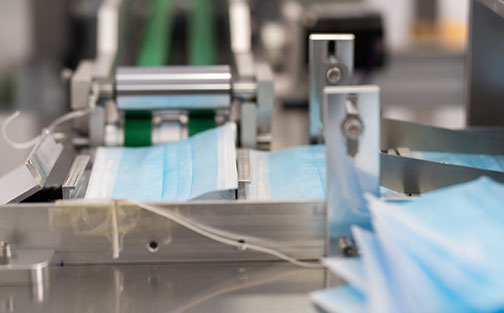

Forming Module: produces the body of the mask, consisting of the supply storage; the main module is supplied by means of TNT feeding spools;

Main module that combines the TNT layers, performing the folding and welding, and, finally, cutting the mask.

Rubber Band Application Module: takes the body of the mask and applies two rubber bands to the side, sewing the rubber band to the body of the mask by means of ultrasound.

Packing and Sterilisation Module: consists of the packaging machine, which wraps the masks individually in plastic film and produces the sealing of the wrapping, making it totally waterproof, with an inert air treatment system inside. The hermetically sealed sterilisation tunnel is equipped with UVC-type ultraviolet lamps with adjustable power.

Packaging Module: made in standard 50-pack carton, the loaded boxes are flattened in the feeder. The machine opens the box, applies the glue to the bottom flaps and folds it.

The equipment has a production capacity of 100 – 120 masks/min, the 400Vac supply has a maximum electrical power of 5Kw. It also features compressed air pressure: 6 bar maximum, as well as contactless sensors (inductive and photoelectric) and variable speed regulated on the HMI console.

For APINEQ, there are no insurmountable challenges.

Schedule a meeting with our team

We provide the finest experts to meet any challenge at all times.